BEAM automation software

The alternative to complex and expensive batch control systems.

- Additional automation layer

- Easy installation

- All-purpose

BEAM: Upgrade Your Automation System Without Reprogramming

Is your automation system outdated and burdened with repetitive tasks? Are you missing essential features like recipe control, data logging, or detailed reporting? Yet, a full system reprogramming is a risk you’d rather avoid.

BEAM is the solution!

With BEAM, you can enhance your existing automation system effortlessly—without the need for complex modifications. This innovative platform seamlessly integrates with your setup and adds powerful functionalities, such as:

- Smart Recipe Control – Automate and standardize processes for greater efficiency.

- Advanced Data Logging – Automatically store all measurements and actions in a central database.

- Insightful Reporting – Quickly generate detailed data reports for better decision-making and quality control.

Suitable for Any Scale of Operation

BEAM is designed to optimize automation across various environments, including:

- Research Plants – Gain precise control over experiments with automated data logging and analysis.

- Lab Plants – Streamline workflows and improve reproducibility in laboratory-scale processes.

- Pilot Plants – Scale up efficiently with advanced monitoring and control functionalities.

- Production Plants – Enhance efficiency, reduce waste, and ensure consistent product quality.

Why Choose BEAM?

- No reprogramming required – BEAM works with your current system, avoiding costly and risky changes.

- Increased efficiency – Reduce manual tasks, boost productivity, and minimize errors.

- Full process control – Gain deep insights into your operations and optimize production with data-driven decisions.

Next generation control & automation

BEAM takes your automation to the next level with intelligent tools like:

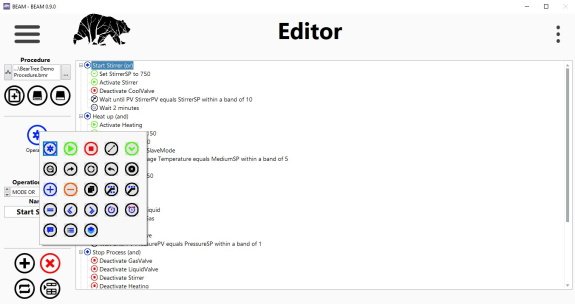

- Procedure (recipe) module: Minimize repetitive tasks, streamline processes, and enhance product quality.

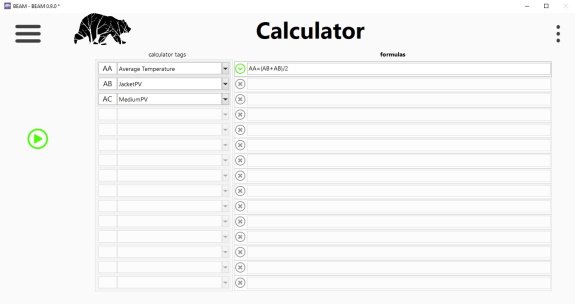

- Calculator function: Automate calculations and support advanced control strategies.

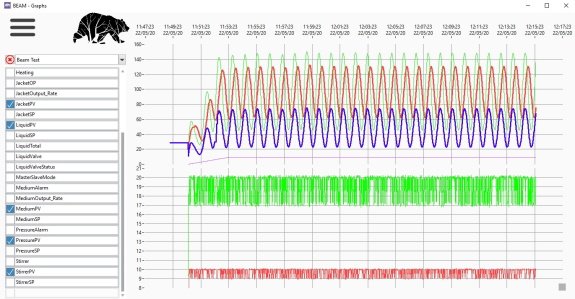

- Graph function: Visualize real-time and historical data for clear process insights.

Integrated Reporting

Turn data into a powerful asset:

- Comprehensive Data Logging – Consolidate all process data into one structured report.

- Standardized, Efficient Reporting – Save time and improve operational insights with clear, structured reports.

Future-Proof Your Automation System with BEAM!

Choose efficiency, control, and innovation—without the risks of full reprogramming.

Procedure editor

Create and edit procedures

Report generator

Customize and generate your reports

Graphs

Show historical AND real time data in these graphs

Calculator

Add mathematical functionality to your unit

What can you expect?

Challenges

- Repetitive actions >> human errors

- Waiting time >> operational inefficiency

- Operational error >> quality inconsistency

- Quality and time loss >> lost production and reputation damage

Results

- Consistent quality

- No time wasted

- No product wasted

- Maximized output

- Improved reputation